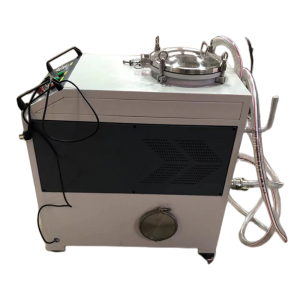

4New DV Series Industrial Vacuum Cleaner

Design Concept

DV series industrial vacuum cleaner, designed to effectively remove contaminants and residues,such as residues and floating oil during machining from the normal use of coolant, from process fluids to increase productivity and improve overall working conditions. DV series vacuum cleaners are an innovative solution that reduces the frequency of fluid changes, prolongs the life of cutting tools and improves the quality of finished products.

Product Application

With DV series industrial vacuum cleaners, residual contaminants and residues can be effectively removed from machining fluids to prevent rapid degradation of fluid quality. Efficient removal of this contaminant reduces the need for frequent fluid changes, which in turn reduces overall production costs and leads to more efficient use of resources. Furthermore, by removing the contaminants present in the fluid, the quality of the finished product is enhanced, which benefits businesses that prioritize quality assurance.

Product Advantage

DV series industrial vacuum cleaners not only help increase productivity, but also improve the working conditions and personal health of employees. A cleaner and purer working environment is good for their physical and mental health as it reduces the risk of any health issues caused by inhaling pollutants. This results in a more motivated workforce who are more productive and focused, which in turn contributes to overall business success.

In short, DV series industrial vacuum cleaners are game changers in the process fluid world. It helps to reduce production costs, improve product quality, and improve working conditions. The machine ensures a smooth production process and ensures that all employees operate in a safe and secure environment.DV series industrial vacuum cleaners are an innovative and effective solution for companies striving to increase production and quality.

Customer Cases