4New LM Series Magnetic Separator

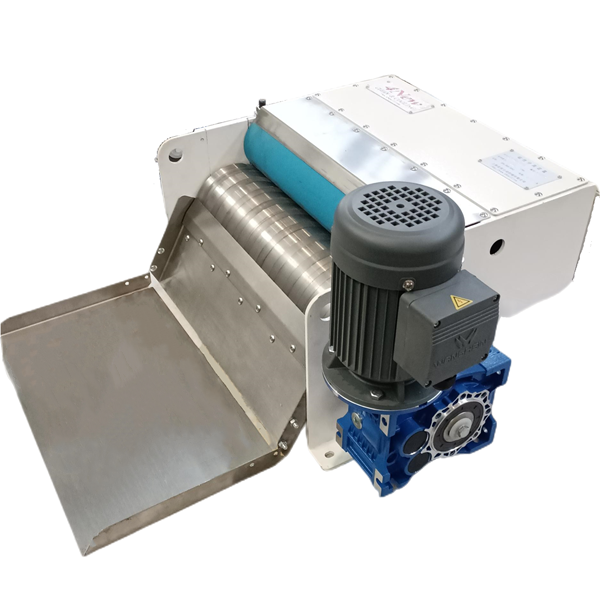

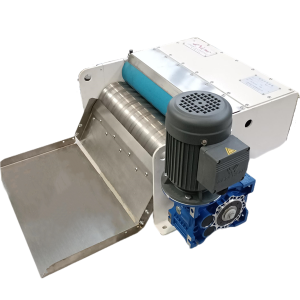

Roller type magnetic separator

The press roll type magnetic separator is mainly composed of a tank, a strong magnetic roller, a rubber roller, a reducer motor, a stainless steel scraper and transmission parts. The dirty cutting fluid flows into the magnetic separator. Through the adsorption of the powerful magnetic drum in the separator, most of the magnetic conductive iron filings, impurities, wear debris, etc. in the dirty fluid are separated and tightly adsorbed on the surface of the magnetic drum. The pre-separated cutting fluid flows out of the bottom water outlet and falls into the lower liquid storage tank. The magnetic drum keeps rotating under the drive of the reduction motor, while the rubber roller installed on the magnetic drum continuously squeezes the residual liquid in the debris impurities, and the squeezed debris impurities are scraped off by the stainless steel scraper tightly pressed on the magnetic drum and fall down the sludge bin.

Disk type magnetic separator

Disk type magnetic separator is mainly composed of a chassis, a disk, a strong magnetic ring, a reduction motor, a stainless steel scraper and transmission parts. The dirty cutting fluid flows into the magnetic separator, and most of the magnetic conductive iron filings and impurities in the dirty fluid are separated by the adsorption of the strong magnetic ring in the magnetic cylinder. The iron scraps and impurities adsorbed on the disk and magnetic ring are scraped off by the stainless steel scraper tightly pressed on the magnetic ring and falls down to the sludge bin, while the cutting fluid after pre-separation flows out of the bottom liquid outlet and falls into the liquid storage tank below.

The magnetic separator is designed to add disc components, which is conducive to improving the adsorption capacity of impurities, protecting the magnetic ring from external force impact, and effectively extending the service life of the magnetic ring.

Double layer disk type magnetic separator

The magnetic separator is mainly composed of a liquid inlet tank body, a high-performance magnetic ring, a reduction motor, a stainless steel scraper, and transmission parts. When dirty oil enter the magnetic separator, most ferrous sludge in the dirty oil are attracted on the surface of magnetic drum, and the liquid is extruded by the roller, the dry sludge is scraped by stainless steel scraper and fall down to the sludge cart.

The capacity of one unit is 50LPM~1000LPM, and have multi way to let the coolant enter. 4New can also supply more larger flow rate or much higher separator efficiency.