Factory wholesale Centrifuge Filtration Systems - 4New LC Series Precoating Filtration System – 4New

Factory wholesale Centrifuge Filtration Systems - 4New LC Series Precoating Filtration System – 4New Detail:

Main Technical Parameters

| Equipment model | LC150 ~ LC4000 |

| Filtering form | High precision precoating filtration, optional magnetic pre separation |

| Applicable machine tool | Grinding machineLathe Honing machine Finishing machine Grinding and polishing machine Transmission test bench |

| Applicable fluid | Grinding oil, emulsion |

| Slag discharge mode | Air pressure dewatering of wear debris, liquid content ≤ 9% |

| Filtering accuracy | 5μm. Optional 1μM secondary filter element |

| Filter flow | 150 ~ 4000lpm, modular design, larger flow, customizable(based on 20 mm viscosity at 40 ° C)²/S, depending on the application) |

| Supply pressure | 3 ~ 70bar, 3 pressure outputs are optional |

| Temperature control capability | ≤0.5°C /10min |

| temperature control | Immersion refrigerator, optional electric heater |

| electric control | PLC+HMI |

| Working power supply | 3PH,380VAC,50HZ |

| Control power supply | 24VDC |

| Working air source | 0.6MPa |

| Noise level | ≤76 dB |

Product Function

LC precoating filtration system achieves deep filtration through precoating of filter aid to realize solid-liquid separation, reuse of purified oil and deoiling discharge of filter residue. The filter adopts backwashing regeneration, which has low consumption, less maintenance and does not affect the quality of oil products.

● Technological Process

User dirty oil reflux → magnetic pre separator → high precision pre coating filtration system → temperature control of liquid purification tank → liquid supply system for machine tool

● Filtration Process

The returned dirty oil is first sent to the magnetic separation device to separate ferromagnetic impurities and then flow into the dirty liquid tank.

The dirty liquid is pumped out by the filter pump and sent to the precoating filter cartridge for precision filtration. The filtered clean oil flows into the liquid purification tank.

The oil stored in the clean liquid tank is temperature controlled (cooled or heated), pumped out by liquid supply pumps with different flow and pressure, and sent to each machine tool through overhead liquid supply pipeline.

● Precoating Process

A certain amount of filter aid is added into the mixing tanx by the feeding screw, which is sent to the filter cylinder through the filter pump after mixing.

When the precoating liquid passes through the filter element, the filter aid is continuously accumulated on the surface of the filter screen to form a high-precision filter layer.

When the filter layer meets the requirements, switch the valve to send the dirty liquid to start filtration.

With the accumulation of more and more impurities on the surface of the filter layer, the filtering amount is less and less. After reaching the preset differential pressure or time, the system stops filtering and discharges the waste oil in the barrel into the sump.

● Dehydration Process

The impurities and dirty oil in the sump tank are sent to the dewatering device through the diaphragm pump.

The system uses compressed air to press out the liquid in the cylinder and return to the dirty liquid tank through the one-way valve on the door cover.

After the liquid removal is completed, the pressure of the system is relieved, and the solid falls into the slag receiving truck from the liquid removal drum.

Customer Cases

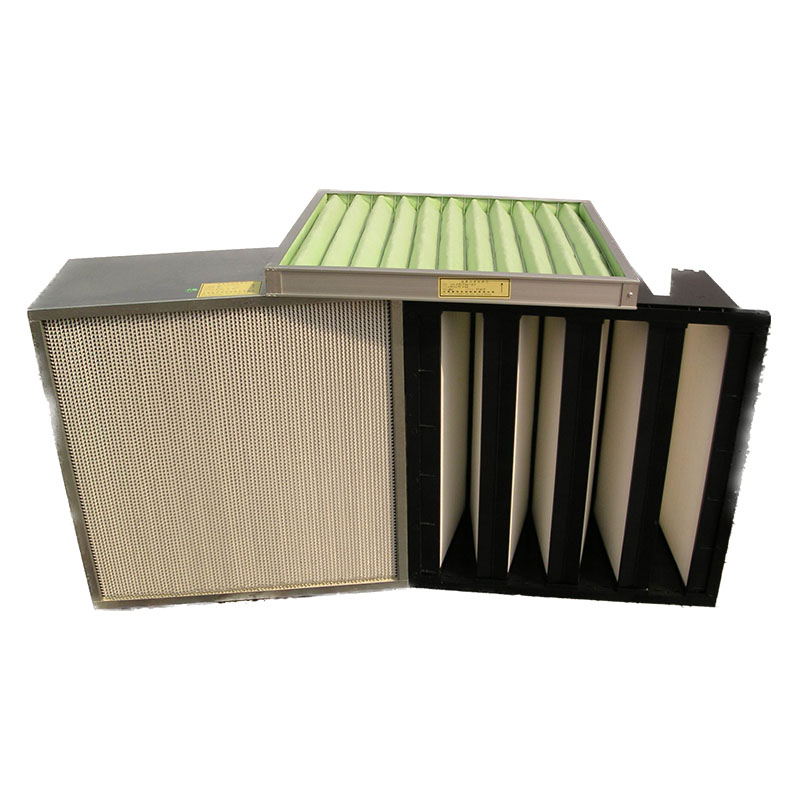

Product detail pictures:

Related Product Guide:

abide by the contract, conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Factory wholesale Centrifuge Filtration Systems - 4New LC Series Precoating Filtration System – 4New , The product will supply to all over the world, such as: Melbourne, Bhutan, London, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!